Water pH : definition and industrial applications

Maintaining the proper pH of water is crucial across industries, from ensuring safe consumption to optimizing industrial processes. Understanding water pH and its implications for quality, safety, and efficiency helps industries meet regulatory standards and achieve operational excellence.

What is Water pH?

Definition and the pH Scale

Water pH measures the concentration of hydrogen ions (H⁺) in water, indicating how acidic or alkaline it is. The pH scale ranges from 0 to 14:

- Acidic water: pH below 7, with a higher ion concentration of hydrogen.

- Neutral water: pH of 7, where hydrogen and hydroxide (OH⁻) ions are balanced.

- Alkaline water: pH above 7, where hydroxide ions outnumber hydrogen ions.

This scale is logarithmic, meaning a one-unit change in pH represents a tenfold difference in hydrogen ion concentration. For example, water with a pH of 6 is ten times more acidic than water with a pH of 7.

How Water pH is Determined

Determining water pH involves precise measurements using specialized tools:

- pH meters: Highly accurate electronic devices commonly used in laboratories and industrial environments.

- Litmus paper: A simple method for quick testing, but less precise.

- Chemical kits: Suitable for field use, providing approximate pH values.

Modern meters often incorporate temperature compensation, ensuring accuracy despite fluctuations in water temperature, which can influence pH readings. Continuous monitoring is essential for industrial systems, as even slight changes in pH can impact processes and product quality.

Acidic, Neutral, and Alkaline Water Explained

- Acidic water: Typically results from high CO₂ levels or industrial contamination. It poses risks such as corrosion and reduced water quality.

- Neutral water: Balanced pH, ideal for drinking and many industrial applications. Neutral water minimizes the risks of adverse chemical reactions.

- Alkaline water: Characterized by its alkalinity, which reflects the water’s ability to neutralize acids. Alkaline water may contain dissolved minerals like bicarbonates, calcium, and magnesium, contributing to its buffering capacity.

Why is Water pH Important?

Impact on Human Health and Consumption

The pH of drinking water has significant implications for human health. Water with a pH outside the recommended range of 6.5 to 8.5 can:

- Corrode pipes, introducing harmful metals like lead or copper into the water supply.

- Affect taste, with acidic water tasting metallic and alkaline water having a soapy flavor.

- Potentially irritate the gastrointestinal tract if consumed over time.

Citizens**’ concerns about water safety often focus on pH and its impact on water quality. Ensuring pH stability requires ongoing monitoring and adjustments to maintain a safe and palatable pH level.

Effects on Aquatic Ecosystems

Aquatic ecosystems are highly sensitive to pH changes. Shifts in water pH can:

- Alter the solubility of nutrients and toxins, impacting aquatic species’ survival.

- Reduce oxygen levels as photosynthetic organisms struggle in non-optimal pH conditions.

- Increase stress on fish and other species, particularly in acidic waters where higher hydrogen ion concentrations can interfere with their biological processes.

Role of pH in Water Quality and Treatment

Water pH is a critical parameter in ensuring effective treatment. It influences:

- Coagulation and sedimentation: The effectiveness of these processes in removing suspended particles depends on maintaining an appropriate pH.

- Disinfection: Many disinfectants, like chlorine, work optimally within a specific pH range. Extreme pH levels can reduce their efficiency.

- Dissolved mineral levels**: pH affects the solubility of minerals, impacting water clarity and taste.

From a scientific view, managing water pH ensures both ecological balance and compliance with regulatory standards for public health.

Challenges of Maintaining Optimal pH Levels in Industry

Variability in Water Sources and Their pH

Water sources such as rivers, lakes, and groundwater exhibit significant variability in pH due to natural and human factors:

- Surface water: More prone to pH fluctuations due to environmental changes and urban runoff.

- Groundwater: Generally stable but can have high alkalinity or acidity based on geological composition.

Industries face challenges in stabilizing water pH when the source’s concentration of dissolved solids and gases fluctuates. Adaptation requires tailored solutions and continuous monitoring.

Corrosion and Scaling Caused by Improper pH Levels

Improper pH levels result in:

- Corrosion: Acidic water can degrade infrastructure, leading to costly repairs and contamination risks.

- Scaling: Alkaline water can deposit mineral scales, reducing heat exchange efficiency and clogging systems.

These issues are particularly challenging in industries with temperature-sensitive processes, where temperature changes exacerbate scaling and corrosion.

Costs Associated with Untreated or Poorly Managed pH

Neglecting water pH management can lead to:

- Increased operational costs from inefficiencies and equipment damage.

- Non-compliance fines and penalties for failing to meet water quality regulations.

- Production delays due to system downtime or product quality issues.

Industrial Applications and pH Requirements

pH Management in Food and Beverage Production

Precise pH control ensures product quality and safety in the food and beverage industry:

- Beverages: Carbonated drinks require acidic water to stabilize carbonation and enhance flavor.

- Food preservation: Pickling and canning processes depend on specific pH ranges to inhibit microbial growth.

- Cleaning and sanitization: Adjusting water pH improves the effectiveness of cleaning agents, ensuring hygiene.

The Role of pH in Pharmaceutical Manufacturing

In pharmaceutical manufacturing, pH influences:

- Formulation stability: Many drugs require precise pH conditions for efficacy.

- Water for Injection (WFI): Ultra-pure water used in drug production must have tightly controlled pH and minimal dissolved ions.

- Sterilization: Water pH affects the efficiency of steam sterilization and chemical disinfection processes.

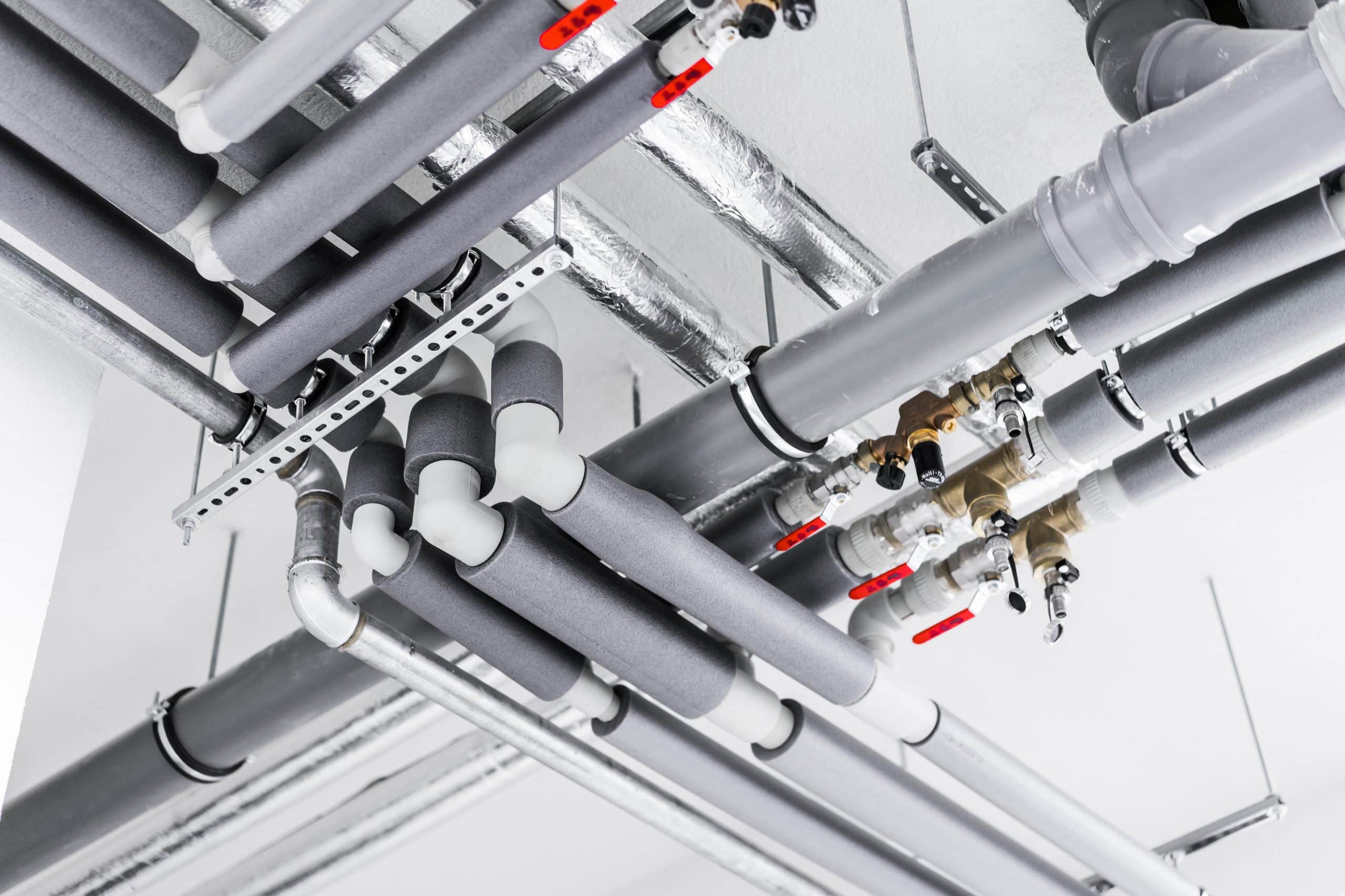

Water pH in Energy Production and Cooling Systems

Power plants and industrial cooling systems rely on balanced pH to:

- Prevent scaling and fouling in heat exchangers and turbines.

- Optimize water flow by minimizing corrosion-related blockages.

- Maintain compliance with environmental regulations for wastewater discharge.

How to Measure and Adjust Water pH in Industrial Processes

Industries must adopt robust systems to measure and adjust water pH effectively:

Measurement Techniques

- Use automated meters with temperature compensation for real-time monitoring.

- Conduct regular manual testing to validate system accuracy.

Adjustment Methods

- Acid addition: Adding sulfuric or hydrochloric acid lowers pH for alkaline water.

- Base addition: Using lime or soda ash increases pH in acidic water.

- Carbon dioxide injection: Reduces alkalinity and adjusts pH in specific applications.

Citizen Engagement

- Encouraging public awareness of water pH helps foster collaboration between communities and industries to address water quality concerns.

- Educating citizens on the importance of pH promotes understanding of water safety and conservation efforts.

Managing water pH is a balance of science, technology, and practical application. By maintaining optimal pH levels, industries can enhance efficiency, protect ecosystems, and ensure compliance with regulations, securing a sustainable future for all.