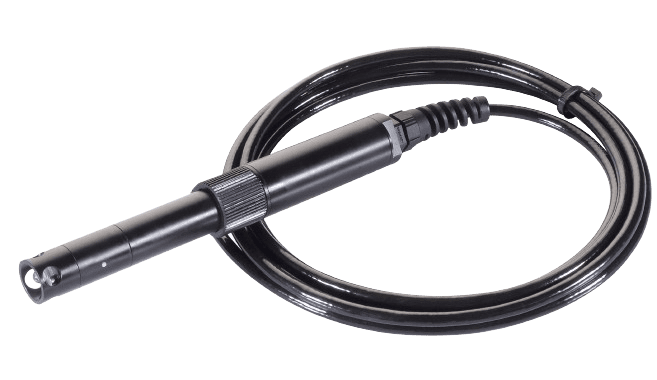

Digital sensor PHEHT Monobloc

The PHEHT cutting-edge sensor excels in measuring pH, ORP, and temperature parameters. Engineered for challenging conditions, it boasts a long-life electrode, digital technology, and Modbus RS485 protocol for seamless integration.

Learn more